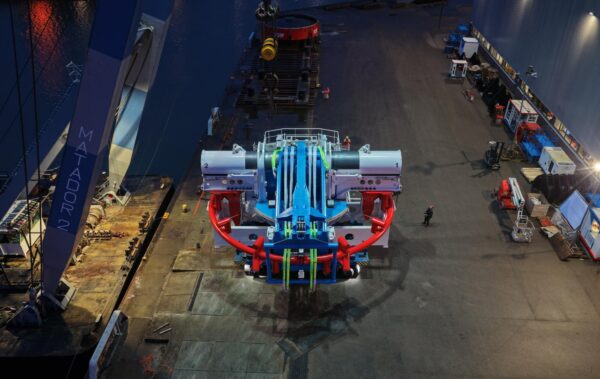

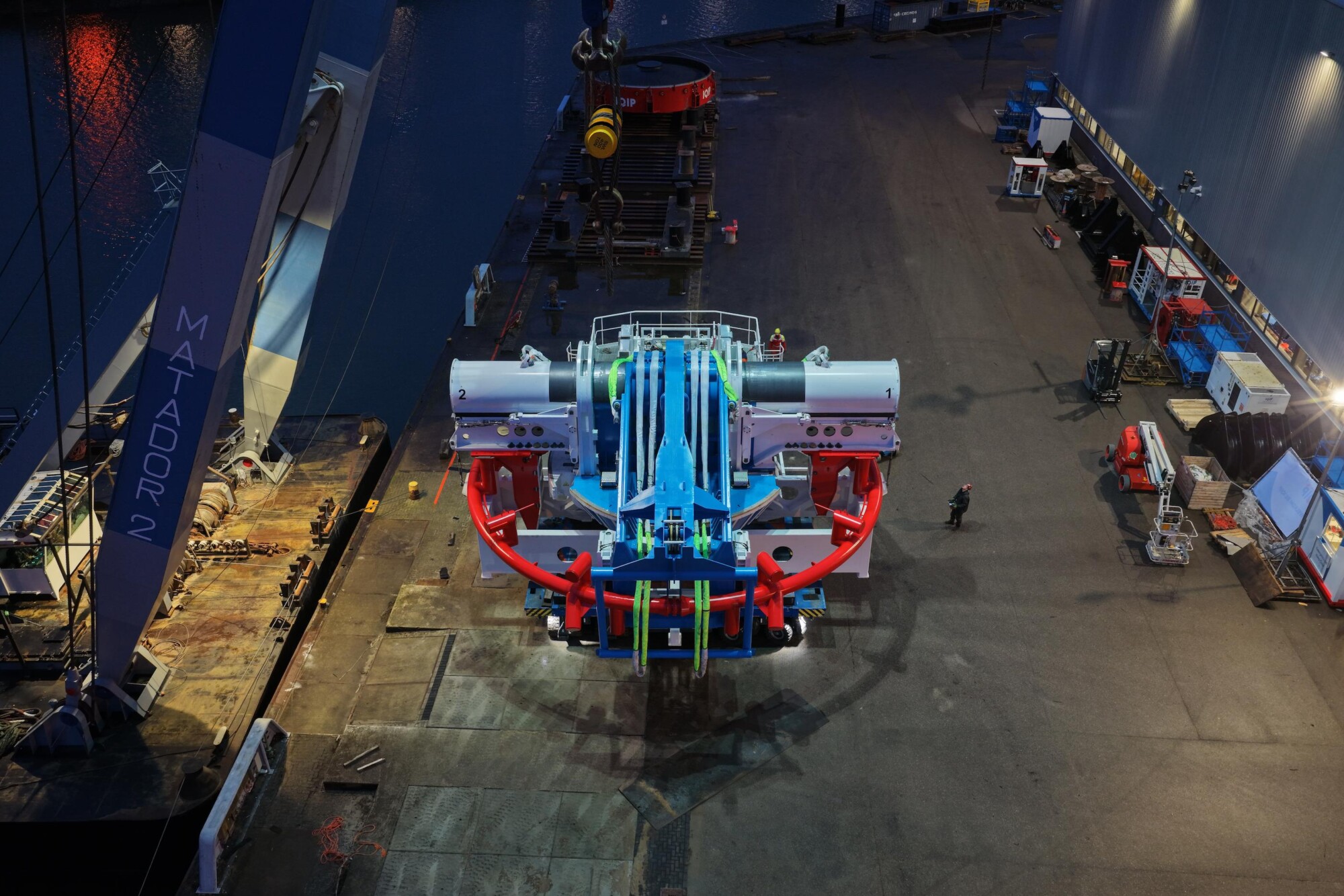

We recently captured the load-out of our new FPUT3500 (Flanged Pile Upending Tool). This impressive tool is now on its way to its first deployment at the Inch Cape Offshore Wind Farm in the Scottish North Sea, and will be available in our rental fleet as of now.

Where FPUTs come into play

Monopiles are transported horizontally on the deck of installation vessels and must be upended before installation. Specifically engineered for this task, the FPUT3500 engages with the L-shaped flange geometry and locks into the top of the monopile via remote control. The crane then lifts the pile into a vertical position. Once upright, the tool disengages remotely and returns to the deck — ensuring a safe, efficient, and “no hands on deck” operation.

Extending lifting capacity for XL monopiles

The FPUT3500 extends lifting capability to 3,500 tons, supporting the future of XL monopiles in offshore wind. Its adjustable width allows handling of monopiles ranging from 7.5 to 9.5 meters in diameter. IQIP has continuously refined its upending technology with enhanced remote control and camera systems, design improvements for free-hanging stabbing from floating vessels, and enhanced safety features built on IQIP’s signature fail-safe principle. Predecessors of the FPUT3500 have proven their reliability on projects such as Kaskasi, Nyuzen, Arcadis Ost 1, Dogger Bank A, B & C, Gode Wind 3, Borkum Riffgrund 3, and Thor.

Full service provider at Inch Cape

IQIP will play a key role in foundation handling and installation in this project. Together with the FPUT3500, our Hydrohammer IQ6 from the IQ-series — the world’s most powerful hammer range — will install 54 XXL monopiles. The IQ6 also features IQIP’s hammer interface socket for seamless connection with the CLT1700 (Combi Lifting Tool), a demonstration in efficiency and safety.

A proud moment

The drone footage beautifully illustrates the scale of this equipment and the complexity of load-out operations — and we can honestly say that makes us proud. Well done to everyone involved!