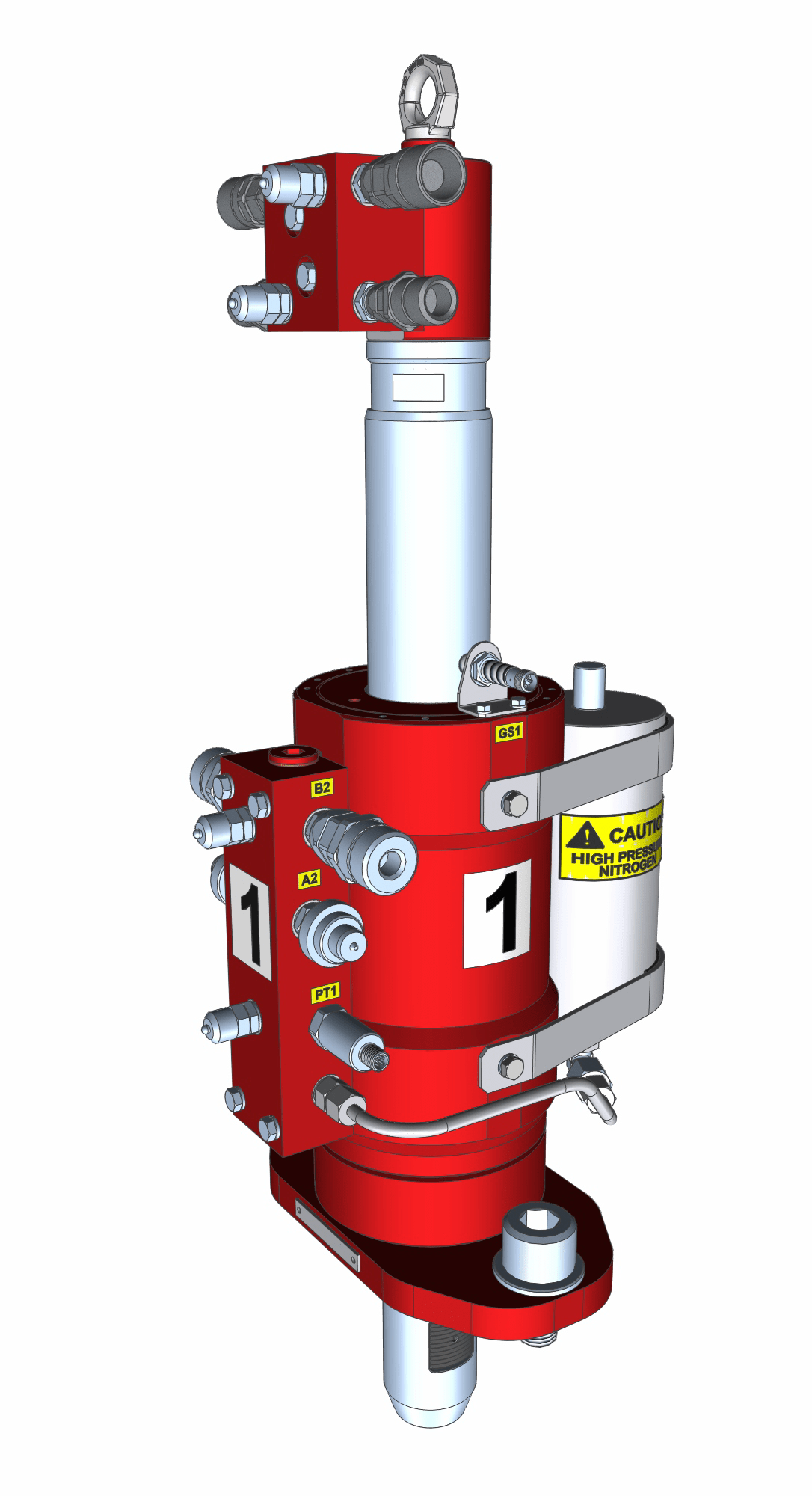

Flange Clamp Tools are used to temporarily secure the axial connection between the flanges of tower and substructure of a wind turbine generator prior and during the installation of permanent bolting. After installing the majority (or all) of the installation bolts, all Flange Clamp Tools are removed.

Once the Flange Clamp Tools are pre-installed and equally divided in the circumference of the given flange, all are connected into one system that can be operated remotely. This increases safety during offshore operations due to the fact that attending personnel during installation is no longer a requirement. Additionally, the temporary connection no longer warrants for a crane vessel during bolt installation, thus reducing installation time and increasing efficiency.

The Flange Clamp Tool is multi-functional and is mostly used at offshore floating wind projects, but can also be used in other on- and offshore projects.