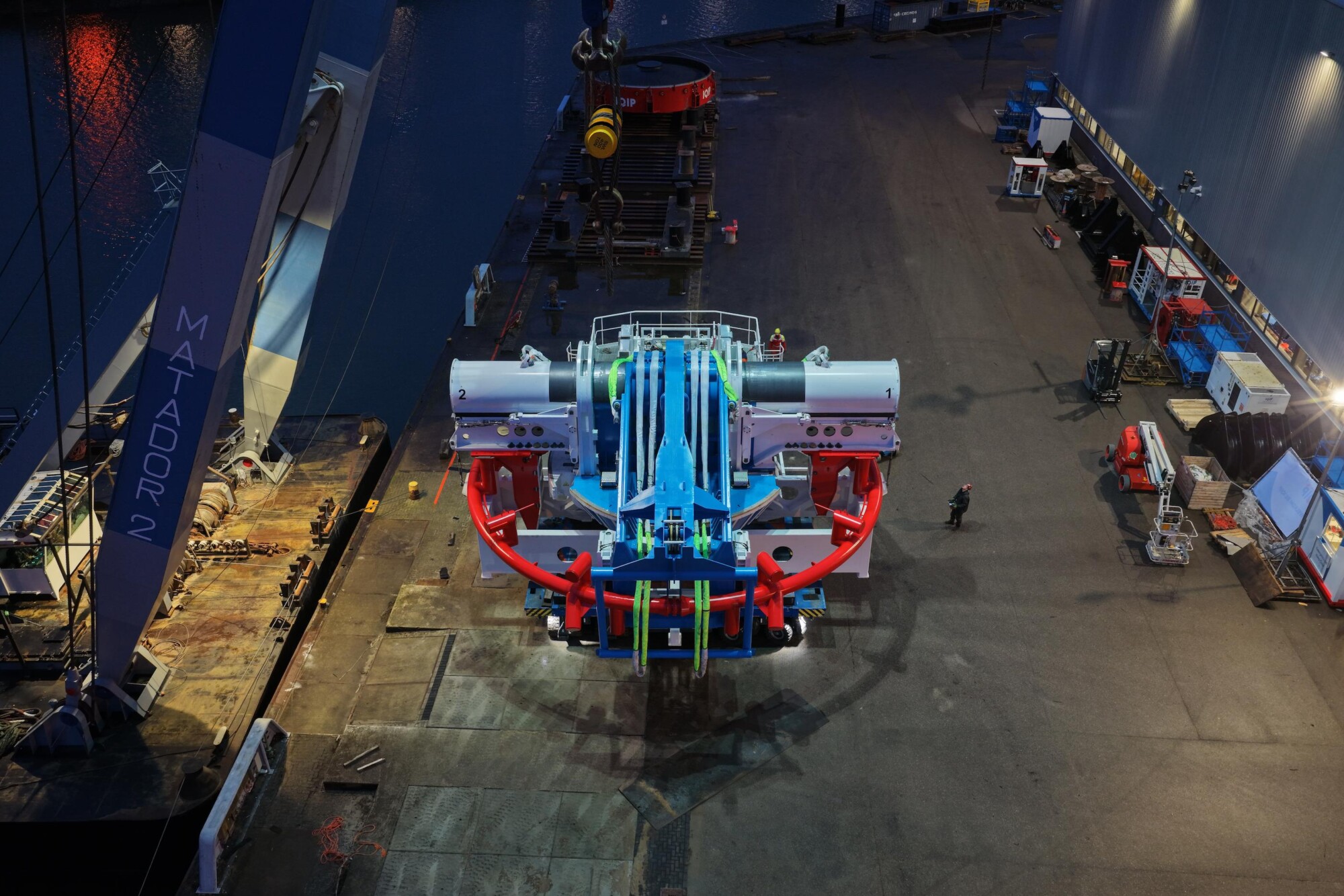

Pile driving, pile handling & lifting

At IQIP, we work closely and safely with our customers and stakeholders to create innovative and sustainable solutions in offshore wind. We recognise the numerous challenges involved in installing foundations for offshore wind turbines. Increasingly stringent environmental standards, deeper offshore areas, larger turbines and thereby larger monopiles, the use of floating installation vessels and the emergence of floating foundations are challenges that we are happy to tackle with our customers.

Through our integrated and professional approach, we provide a secure and cost-effective service based on our proven track record. By consistently offering quality and customised solutions that optimise the operational efficiency of customers, IQIP acquires an international leading position as a supplier of total solutions for offshore wind projects. By working closely together with our customers we can ensure maximum installation windows and mitigation of risk during the lifetime of a project and beyond.